CPC Circuit Protective Conductor. What is a CPC? - Electrical Faults Fixed

What exactly is a CPC when we talk about electrical installations, wiring and systems? CPC stands for Circuit Protective Conductor (sometimes referred to as the EARTH) which is the wire in electrical systems that connects any exposed conductive parts of equipment to the main earthing terminal of the electrical system. What exactly does this mean?

1) CPC in Electrical Installations

When we think about electrical wiring, there is the Line Conductor (sometimes referred to as "the live"), the Neutral conductor (which is also a "live conductor") and the earth. The earth is actually the circuit protective conductor and is responsible for removing electrical fault currents, from the electrical circuit, making a circuit breaker or RCD / GFCI device trip and goes some way to preventing electric shock. The CPC helps to achieve automatic disconnection of supply by tripping or blowing protective devices in the event of an electrical fault.

There should be a CPC in almost all modern electrical circuits that were wired recently. In accordance with UK wiring regulations BS7671 regulation 411.3.1.1 a CPC needs to be run to each point whether needed or not by the equipment on the circuit. The CPC is integral to most UK cabling that is used for fixed wiring in homes and other properties with some exceptions.

Back to top2) Difference between the CPC and Earth

The earth wire or Earthing conductor, is the wire responsible for connecting the Main Earthing Terminal to the means of earthing. The means of earthing could be the earth electrode (earth rod, earth mat etc) for the installation or the suppliers means of earthing. The CPCs of each circuit connect into the main earthing terminal and the earthing conductor then links these to EARTH.

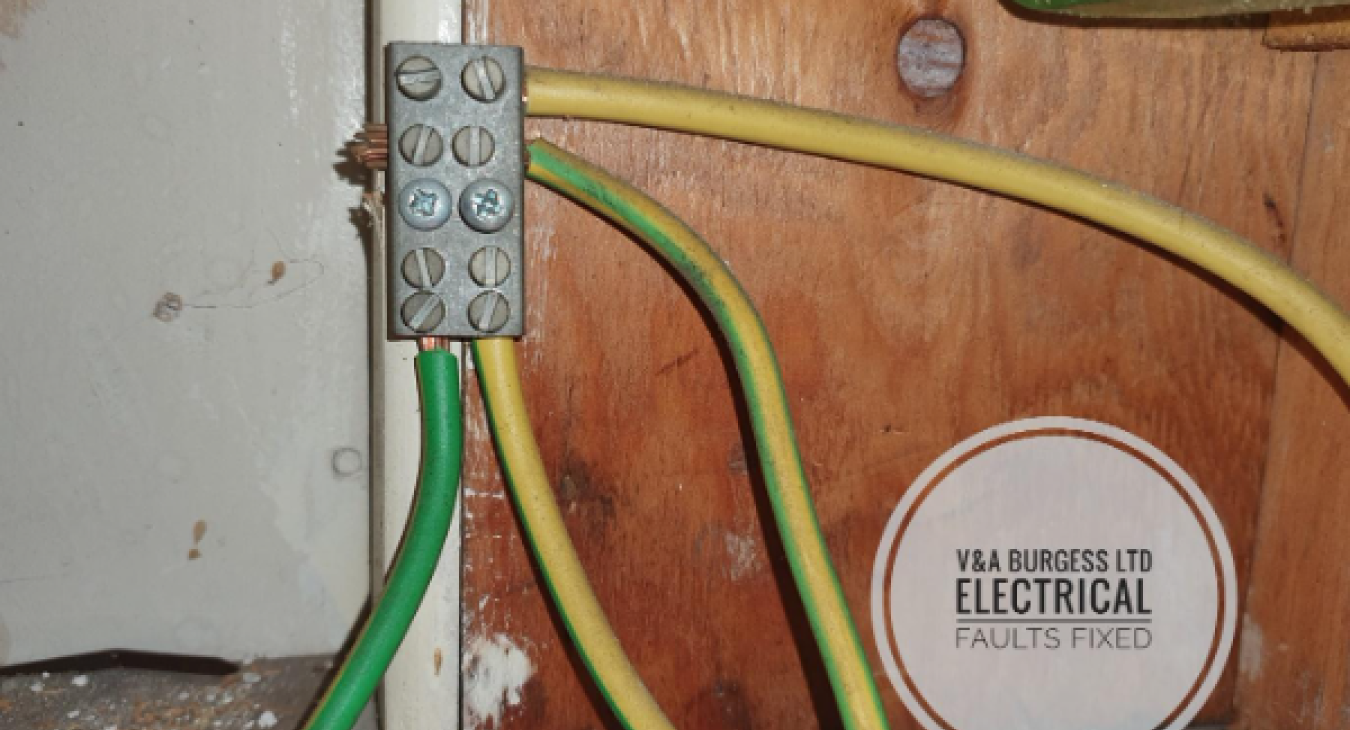

Back to top3) Colour of CPC and Earth

The cover of the CPC and Earth cables in modern wiring systems should be a green / yellow mixture with one of the colours covering at least 30% of the surface area and at most 70%. Bare conductors should be sleeved.

In older wiring systems the CPC was often light or dark green only but this changed in recent years.

Back to top4) Regulations Governing CPC, its size and installation

The regulations in the UK surrounding the use and installation of the CPC can be found in the IET BS7671 wiring regulations. Where a CPC is integral to a cable, as it the case for 6242y (commonly known as twin and earth in the industry), its size has already been calculated and is deemed to be acceptable when the cable is installed in accordance with the wiring regulations.

Where a CPC is NOT present in a cable already some consideration needs to be taken. Where cables are run in trunking or conduit and are single conductors (6491x and 6491B for example) the CPC size will normally need to be the same as the LIVE conductors.

Back to top5) Materials used for a CPC

As with most modern electrical cabling, the CPC is normally manufactured from copper but in the case of Steel Wire Armored (or Armoured UK) cables, the steel wiring that protects the cable is often used as the CPC for that circuit. In these cases, there is a calculation that needs to be carried out to ascertain if the steel wires will provide a sufficiently low resistance for the CPC.

Where galvanized steel trunking, and galvanized steel conduit are used as cable containment in an electrical system, these can sometimes be used as the circuit protective conductor for the circuit. If the construction of these containment systems is done correctly, a very low value of resistance can be achieved beyond the value of using a CPC cable.

Back to top6) Importance of the CPC sizing and connections

The CPC cross-sectional area and construction may vary depending upon the use of an electrical circuit. For example, where an electrical circuit supplies IT systems a separate conductor may need to be run for the CPC as electrical currents are expected to be present in the CPC. In these cases, a high-integrity protective connection will be needed in accordance with BS7671 543.7.1.203.

Back to top7) CPC Testing and Maintenance

When installing new electrical circuits, new wiring or extending existing wiring, it is necessary to ensure that the CPC is present. Using a calibrated low resistance ohmmeter or multi-function tester, CPC continuity must be confirmed. This is a form of testing carried out on final circuits by electrical contractors that have the knowledge, experience, and test equipment to do so.

The circuit is safely isolated using approved equipment and safe isolation techniques and then the CPC resistance is measured using an appropriate technique such as those set out in IET Guidance Note 3. Once the CPC has been proved continuous, of low enough resistance and terminated correctly throughout the circuit, further tests can be conducted.

The continuity of CPC test is the first test that is carried out whilst dead testing and without a successful result, further testing cannot be carried out with meaningful results.

Back to top8) Common CPC problems

One of the major issues that can occur, particularly in a domestic property is that of DIY work and accidents. One of the most common issues that I see is that of a broken CPC in the installation. This is often caused by DIY light fitting installation where the CPC is not installed correctly or omitted altogether which then breaks continuity of CPC for the rest of the electrical circuit.

The danger with a broken CPC is that the lighting will continue to function in a seemingly normal manner so a missing connection would not be noticed. When an electrical fault develops however, any metalwork on the lighting circuit will become and remain live meaning that there is a strong likelihood that someone could receive a fatal shock.

The other CPC problem I regularly see is where a cable is drilled through and the CPC becomes broken. The break is caused by either the drill hitting the wire or from the resultant mini explosion inside the cable as the CPC carries the fault away. The electrical panel, fuse box, or consumer unit will normally trip and then the homeowner resets the switch, the lights come back on and they think everything is fine. But there is no CPC in the circuit now!!

A CPC to socket outlets is also vital and is commonly broken in domestic properties. Many properties come as standard with plastic switches and socket fronts which are not as aesthetically pleasing to the eye as chrome, steel, and other metal finishes. For this reason, homeowners regularly change them and take it upon themselves to do so. No testing is carried out as they have neither the knowledge, test equipment or understanding of the need to do so and as such, cables can fall out, not be connected or break during the installation process.

Back to top9) Summary

An earth cable and a CPC are vital to the safe functioning of an electrical system. Testing, installation and maintenance of the CPC and electrical system should only be carried out by a professional electrician who has the knowledge, equipment, and experience to be able to safely work on the system. A CPC can be missing and the electrical system will continue to function until there is a problem when serious danger will exist.

Back to top

Read more articles

- Log in to post comments