Galvanized Steel Back Box

1) What is an electrical back box, what do they do and what type do you need?

There are a range of back boxes on the market and each has a slightly different purpose or can be modified to fit a particular environment. The back box is designed to contain electrical wiring AND to hold an electrical accessory in place.

Different back boxes will have different features that can be used so let us look at the types:

- Galvanized Steel Back Box

- Surface Mount Box

- Plasterboard Pattress

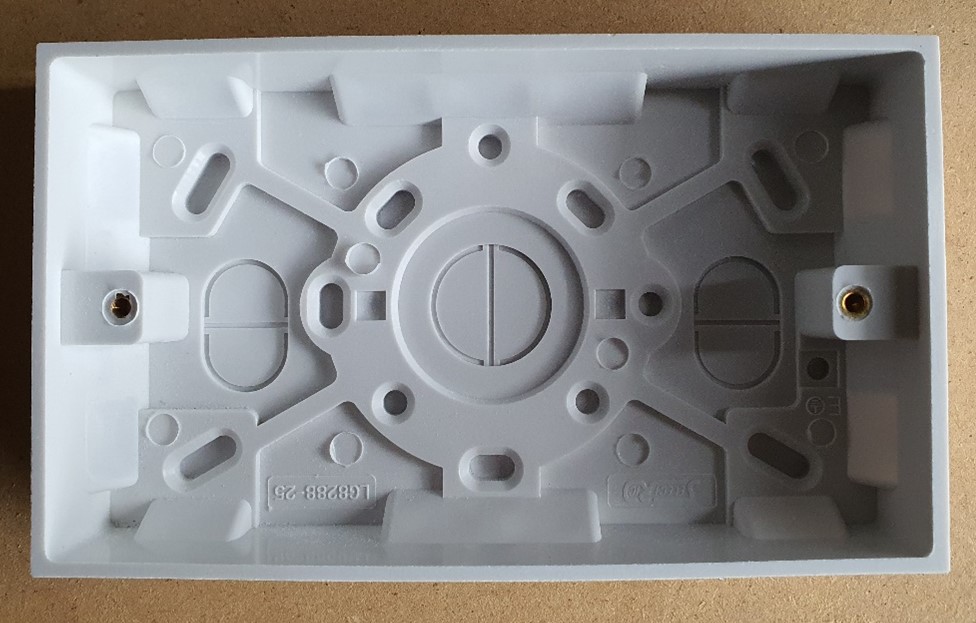

2) Galvanized Steel Back Box

The photograph above shows a galvanized metal ELECTRICAL BACK BOX. This type of box is typically installed in solid walls of masonry construction. There are several circular discs that can be removed to allow for cable entry points.

The metal boxes come in a variety of depths including 16mm, 25mm, 32mm and 47mm deep. The shallow boxes are often used in lighting circuits for light switches where little depth is needed for the switch mechanism and thin cables are used for the circuit. The deeper boxes will require a longer screw than the shallower boxes and may require a very long screw if also installed behind kitchen tiles!

The deeper boxes are used where a thick cable and deep electrical accessory will be installed, such examples would be cooker switches or electric shower isolators.

As the box is metal, there is an earthing requirement for the box to prevent it becoming live under fault conditions and to prevent the risk of electrical shocks.

In 2024, it is sufficient under the safety wiring regulations to have a fixed lug in the box and for the earth to be provided by the electrical accessory that is screwed in to the box. Best practice would be to earth the back box as well with a separate fly lead.

This type of box is sunk into masonry by an electrician. The electrician channels or chases out the masonry surface and then fits the box into place, normally with a couple of screws where the substrate allows.

The boxes come in a variety of sizes to allow for the installation of a 1 gang, 2 gang, 1 + 1 gang, 1 + 2 gang electrical accessory such that single sockets and double sockets can be installed in the same box. There are large back boxes that allow the installation of several sockets to form a media center outlet.

The galvanized 2 gang metal back box has 2 lugs that are used for securing electrical accessories. The 1 gang metal back boxes often have more than two lugs to allow the boxes to be rotated during installation. The lugs on these boxes can be repaired, re threaded or the box otherwise modified if they become damaged. One of the lugs is usually an adjustable bracket type to allow the electrical accessory to be installed and then levelled as required.

Back to top3) The Surface Mount Box

The surface mount box is designed to be installed on the surface of the wall or ceiling. It is manufactured from Plastic or PVC. The two different types operate slightly differently. The surface mount box is used in masonry installations or in plasterboard over timber installations where required.

The surface mount boxes do not have an adjustable lug like the galvanized box so installation needs to be as close to level as possible. Some movement is possible as the back of the box has several holes which allow for fixing and there is some movement available should the box not be perfectly level.

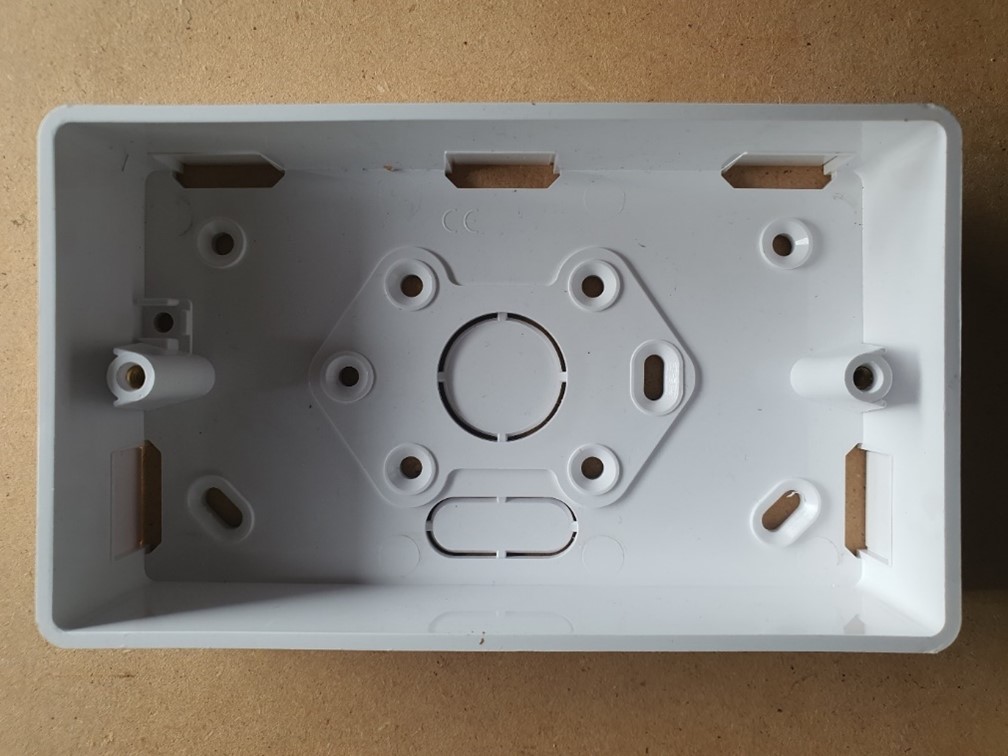

3.1) Plastic Surface Mount Box

The plastic back boxes or surface mount boxes are the cheapest alternative for surface mounting and are suited to areas where the aesthetic is not that important and where the cables may be installed in trunking or clipped where little to no risk of mechanical damage exists.

The plastic boxes have a variety of knockouts which can be removed to allow for cable entry points. Whilst these boxes are relatively cheap, they are also very brittle and will shatter if care is not taken with removing cable entry points.

(Plastic Surface Mount Box)

The plastic electrical back box has two lugs for the 3.5mm machine fixing screws as is the case with the metal boxes but should one of these lugs snap, there are few available products on the market to repair them and the box will likely need to be replaced entirely.

3.2) The PVC surface Mount Box

The PVC (polyvinyl chloride) electrical box is more resilient than the plastic surface mount ELECTRICAL BACK BOX as it is made from a more flexible material. It can be easily drilled or cut without shattering like a plastic box would.

(PVC Surface Mount Box)

These boxes will also have some preinstalled knockouts to accept trunking or conduit installations depending on the requirements of the design. These boxes cost slightly more than the plastic counterpart but are less likely to break during installation and use.

The PVC box also has two lugs like the plastic box, whilst these lugs are also not generally repairable, they are less likely to break in comparison with the plastic boxes. There are many cable entry points on the top, bottom, sides, and rear of the box to allow maximum installation flexibility.

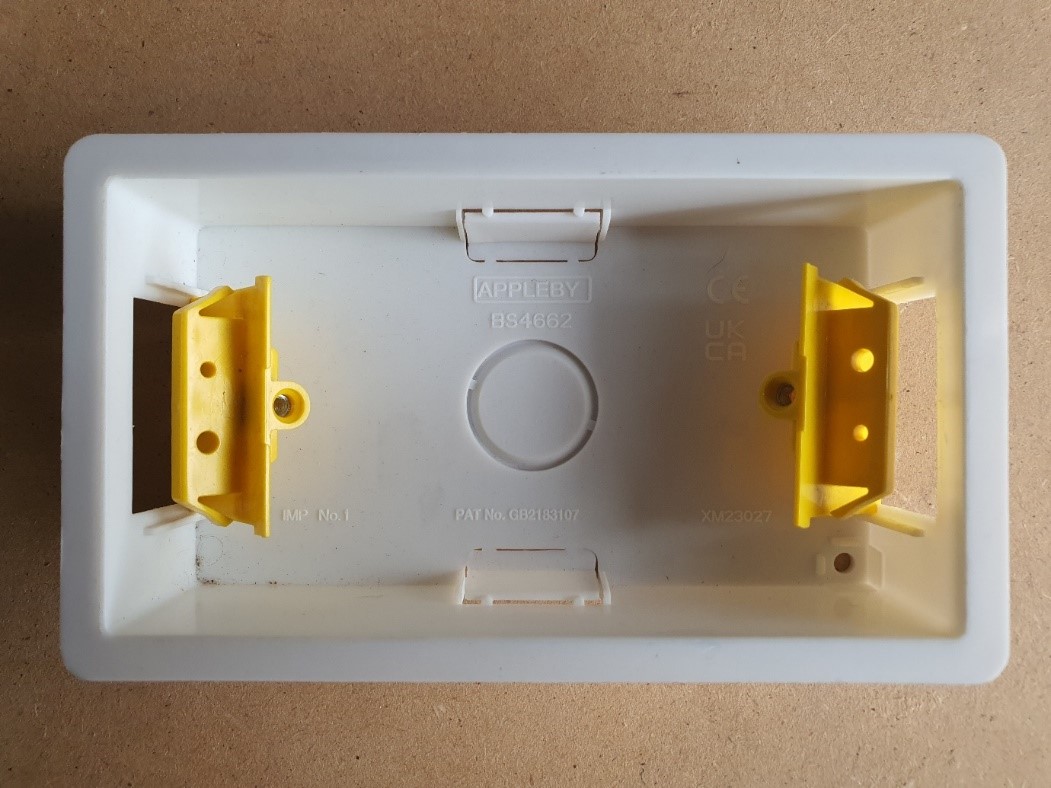

3.3) The Plasterboard Pattress

Seen below, these boxes are also known as dry lining boxes. This is a 2 gang or ‘double’ box but there is also a single (square box) dry lining box available as well as the 2 + 1 set up.

These boxes are designed to be installed in plasterboard walls, they have these adjustable lugs (pictured yellow) that lock into place behind the plasterboard and tighten up as the screws are inserted and tightened.

(Plasterboard Pattress)

Should the thread on one of these boxes become damaged, it is possible to replace the lug entirely but this will often need to be with that of the same manufacturer.

There are cable entry points on the top, bottom, and rear of these boxes for easy installation. The plasterboard pattress comes in various depths including 35 mm depth and 47 mm depth.

Back to top4) Common Questions

4.1) How deep should a galvanized box be for sockets?

A standard double or single plug socket can easily be installed into a 25mm deep galvanized steel ELECTRICAL BACK BOX. Where the socket has USB ports as part of its construction, most will require a 35mm depth back box to safely install the wiring behind.

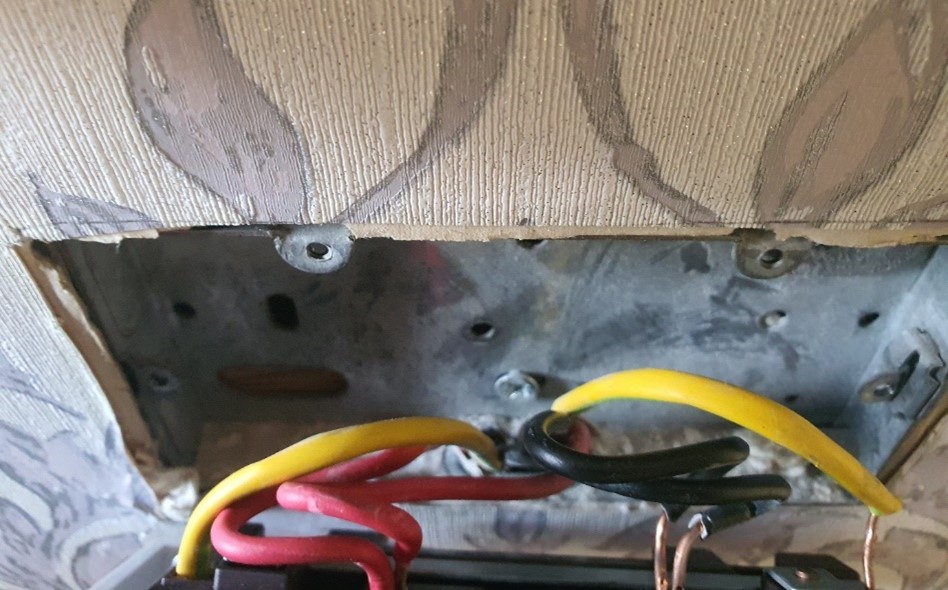

The photograph below shows a double socket installed into a 16mm back box. There was simply not enough room to safely accommodate the cables in this box and as a result the box was hanging off the wall with a gap behind. This can lead to burnt wires and a burnt plug socket.

To rectify a situation such as this, we would require a spacer to sit between the wall and the socket to safely provide some more room at the back of the socket for the wiring.

(2 gang metal box with inadequate space)

4.2) What depth back box is required for light switches?

For a standard light switch where there is only a switch wire present in the back of the switch, a 1 gang 16mm deep galvanized back box is sufficient for the installation.

Where a dimmer is required to be fitted, most will require a 25mm deep back box or a spacer to safely accommodate the wiring.

Where the wiring junction for each light is made at the rear of the switch, a 25mm deep box will be required to safely terminate wiring without trapping or crushing cables. Crushed cables can lead to an unwanted tripping situation and this may be a tricky fault to pin down.

Back to top5) Summary

Electrical fittings require a secure enclosure for wiring connections. Pattress boxes, galvanized boxes and surface mounted boxes are ideal for this purpose. Care should be taken to ensure that this protective housing is installed correctly and unlikely to become damaged during normal use.

When selecting outlet boxes, consideration should be given to the intended and future purpose of the box. Smart home accessories are becoming more common and with the additional technology contained in these electrical accessories they often require a little more space in the box.

Read more articles

- Log in to post comments