What is an electrical junction? Why do we need a box? - Electrical Faults Fixed

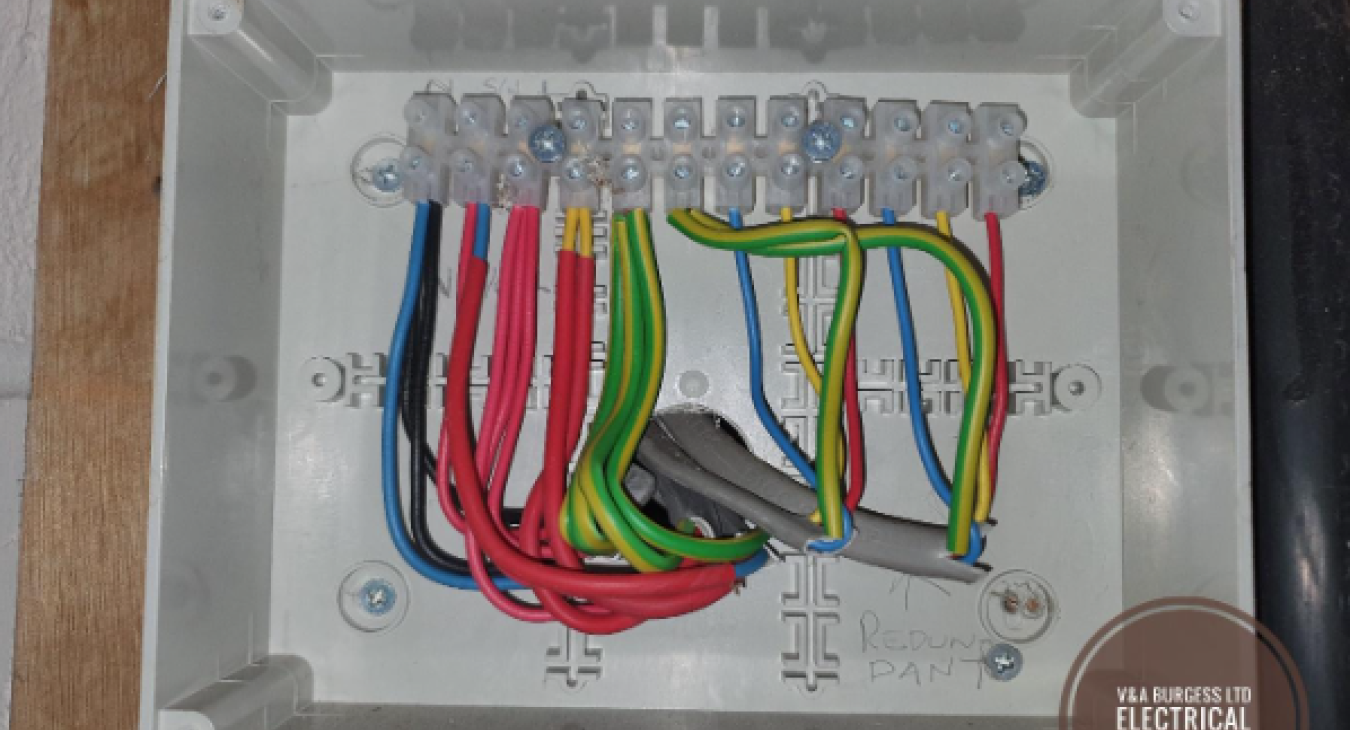

Electrical wires carry the electrical current around the wiring in our homes and businesses. Throughout the electrical circuit it will be necessary to join wires together to send power to other parts of the building. Where this happens, we create an Electrical Junction.

The ELECTRICAL JUNCTION is a place where wiring is split and power is diverted from one place to another, electrical connections generally need to be installed in a safe place and mainly accessible should any new wires need to be added or maintenance carried out.

How is an electrical junction made?

Junction boxes can be metal boxes, plastic boxes with or without a removable cover. There are many types of junction boxes on the market and each will require a slightly different method of installation.

Each junction should be compliant with electrical codes in your area and installed in accordance with the manufacturers’ instructions. There are several things to consider when making an electrical junction including:

- Type of environment

- Power handling capability

- Material of construction

- Costs

- Accessibility

Type of environment

Where a junction is to be installed into harsh environmental conditions, the rating of the junction should be such as to withstand its conditions without adversely affecting the wiring.

If we were to install an indoor junction outdoors then it is highly likely that the ELECTRICAL JUNCTION will not withstand its environment for very long.

Each junction should have an IP rating from the manufacturer stating its capabilities for withstanding water and dust ingress. The IP rating should be highest where lots of water or submersion is expected in order to prevent the electrical enclosure from letting in water.

Where indoor junctions are to be installed, they need not have the capability to withstand such arduous conditions.

Power handling capability

Electrical fires can easily occur where wiring or junctions are overloaded. The power handling capability of an electrical junction is a crucial component in ensuring that a home’s electrical system is safe and suitable for use.

Each critical component of an electrical junction will be designed by the manufacturer to safely handle the rated electrical current.

The purpose of an electrical junction box is to split power therefore, it is likely that the electrical wiring and electrical wire connections at this point will handle more power than at other parts of the circuit.

Material of construction

An outdoor junction box will be designed primarily for outdoor use and as such it is unlikely that metal junction boxes will fulfil the requirements of the harsh weather conditions it is likely to experience.

Where weatherproof junction boxes to be installed, a PVC or plastic is often a better choice for outdoors and many manufacturers only produce PVC or plastic outdoor junction boxes to prevent rust and corrosion.

Plastic junction boxes are suitable for indoor and outdoor use and are less likely to suffer adversely in the outdoor environment. Not all plastic junction boxes may be suitable for installation outdoors however, local building codes should be checked before installation to ensure that the electrical work complies.

Without proper installation in accordance with the manufacturer’s guidelines, it is likely that even the highest quality types of electrical boxes with the best IP rating will survive the outdoors.

Costs

The more manufacturing that goes into a junction box, the higher the cost is likely to be. The manufacturer will have to conduct research into waterproofing, dustproofing, and impact damage before certifying different types of electrical boxes for use in different environments.

These costs are passed on to the consumer and installer of their product.

An indoor rated ELECTRICAL JUNCTION is generally less costly than one that must be installed outdoors.

Accessibility

Before installation we have to consider how any fixture boxes, wire splices or electrical box covers will be affected now and in the future. Will we be able to access the connections for maintenance and inspection going forward or are they likely to be buried?

Different types of electrical junction boxes will need differing amounts of maintenance.

What is a maintenance free junction?

In electrical installations we must ensure that safety is our primary concern. For this reason, junctions must remain accessible where necessary. Electrical problems can occur without prior warning and the ability to access all connections is very important so repairs can be carried out and electrical faults traced.

A maintenance free junction is one that requires no further access for future maintenance. The manufacturer of the junction box assembly will specify if their junction is able to be installed ‘maintenance free’ and the requirements for achieving that.

What wiring connections need access?

Connections at the main electrical panel, ceiling fans, lights, power outlets and switches will need access for future maintenance and inspection. Connections that may not need access for future inspection and maintenance are usually those that are manufacturer approved for burying in a floor cavity, attic space or in the wall and have been deemed maintenance free.

Connections made using crimping tools and heat shrink tubing are usually deemed maintenance free and suitable for burial as access should not be needed. You should check your national electrical code or local wiring regulations for your area to ascertain if your planned ELECTRICAL JUNCTION is deemed maintenance free.

Summary

Without careful planning, research, and installation, buried electrical junctions could lead to short circuit, electrical hazards, or a fire hazard. If in doubt, consult a qualified electrician and ensure that all wiring codes are followed.

Only junctions approved as maintenance free should ever be buried and wherever possible, buried electrical junctions should be avoided altogether.

Electrical junctions are a weak point in the wiring system and are the most common area where burnt wiring and electrical faults occur. As such, great care should be taken when installing any wiring in a junction box to ensure that manufacturers guidelines are followed, that no mechanical strain is present on cabling or connections and to ensure best practices are followed.

Read more articles

- Log in to post comments