Electrical problems can occur in all places throughout an electrical system due to a number of reasons. One of the most common issues I see as a qualified electrician is that appliances regularly cause issues. If you have a WASHING MACHINE PLUG MELTED it can be a real concern a serious electrical danger. As such, it’s important to understand why this occurs and what can be done about it. Why does a washing machine plug melt? It’s always down to excessive heat! How is that heat generated? We discuss this and more in the following article.

1) What causes heat?

As electrical current flows through your home's wiring it comes into contact with terminations, connections, and resistances. Each termination of a cable that occurs is a potential weak point for future problems. Over time cables can work their way loose in terminations and connections which causes a higher resistance than intended for electrical current to flow. Where there is high resistance, heat is generated, sometimes to worrying levels. Connections and terminations work loose for several reasons:

- The natural heating and cooling of the wiring

- Vibrations

- Movement through impact or activity

2) Heating and Cooling

Where electrical current flows in a circuit, heat is generated through the movement of the electrons. The more electrical current that flows the larger the heating effect that occurs. Metals expand and contract when they are heated and cooled and different metals will have a different rate of expansion and contraction. As wiring is made of copper or aluminum, it is susceptible to expansion and contraction through heating. As most terminals are made of brass, these also expand and contract through heating. These different metals will expand and contract at different rates causing loosening of the connections over time.

Back to top3) Vibrations

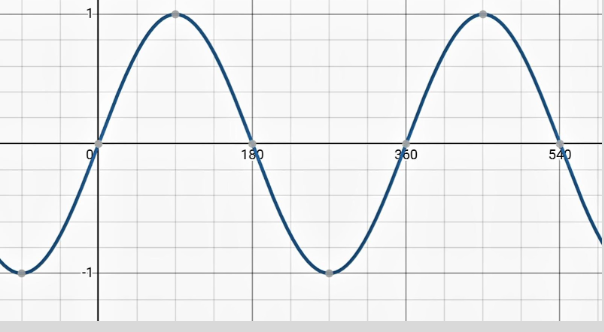

The supply frequency is 60hz in North America and 50hz across Europe. The frequency is the number of times that generated electricity will complete a full cycle from 0 degrees to 360 degrees. This can be seen on an oscilloscope as a sine wave. Pictured below.

One full cycle begins at 0 and ends at 360. In a 50Hz supply system, this cycle happens 50 times per second, in a 60Hz supply system the cycle happens 60 times per second.

The constant cycling of the alternating current electrical supply causes vibrations and, along with the heating and cooling due to expansion and contraction, this can cause connections to loosen over time.

Back to top4) Loose Connections Cause Fires

A loose connection is one of the major reasons for electrical fires. If there is a burning smell, fishy plastic smell or smoke from any electrical equipment, accessories or wiring then its highly likely that you have problems with a poor connection that is generating enough heat to start an electrical fire. Professional electricians can inspect and test circuit resistances to determine if there are loose connections on wiring throughout your property.

(Photo: Burnt Plug Socket)

Back to top5) Movement through impact or activity

In every home, there are impacts to sockets, walls, floors, vibrations caused through general movement throughout the property and disruption to power cables as they are knocked or yanked. There are a number of external influences that can affect the operation of the wiring system and in some cases, these influences can contribute to wiring loosening over time.

Back to top6) High Powered Home Appliances

Wherever there are high-powered home appliances, such as those that contain a heating element, there is often a common problem that occurs at the socket outlet. The outcome of this is usually a burnt or melted plug socket. High powered appliances can aggravate weakened connections or terminations, overload a double plug socket, or overheat plug top fuses not intended for continuous loading.

Where there is an electric dryer and washing machine attached to a single socket or double socket, then it is highly likely that there is a fire hazard. Certainly, in the UK most single and double sockets can only handle 13 amps of electrical current before they become overloaded. Other high demand appliances can overload sockets so check the data badge on each appliance before combining into a single outlet.

High powered appliances can demand 10 amps each easily overloading a typical plug socket. This much current generates heat very quickly and will cause electrical faults to occur, notably overheating and melting to the rear of the plug socket with cracking and discolouration across the front.

Back to top7) Washing Machine Plug Melted

Where you have a washing machine plug melted or tumble dryer plug melted the common causes are:

- Fuse Holder loose in plug top

- Worn out plug socket

- Faulty internal plug connections

- Loose Connections at Back of Socket

The result is usually a burnt outlet and a possible breaker tripping. Where a washing machine plug has melted, some investigation into the cause is necessary not only for peace of mind but to identify the source of the problem.

Back to top8) Fuse Holder Loose in Plug top

Most new appliances will come with a moulded plug. A moulded plug prevents access to the internal connections and only allows for replacement of the fuse. The fuse holder itself is not a perfect design as the fuse is held in with friction only and as such, this relies on the metal clips to be sufficiently tight to hold the fuse AND make a perfect electrical connection.

Where the clips are a little too loose, this can create a vicious circle of high resistance, heat, higher resistance created by the heat and yet more heat! Once this process starts metals can tarnish adding to the impedance to the current flow and the danger of the situation further increases until the risk of house fires is imminent.

Back to top9) Worn Out Plug Socket

Electrical accessories like plug sockets and switches have internal metal parts. Many of these metal parts also move during operation. Over time, metals that are exposed to air, moisture and dust can degrade. Dirt can form on contacts and metals can tarnish or rust all of which cause a higher resistance than intended by the manufacturer of the products. Good contact between metals is essential to ensure high conductivity and low resistance are maintained.

(Photo: Cracked Plug Socket)

Back to top10) Faulty internal plug connections

Where the internal connections of a plug become loose or faulty, electrical arcing can occur along with high resistances. This is more of an issue if moulded plug tops begin to fail as the connections cannot be re-terminated or checked. A damaged plug is at risk of a lot of heat developing or possible electrical shock hazards.

Back to top11) Summary

If you find that your WASHING MACHINE PLUG MELTED then there are many possible causes from electrical faults, poor connections and damage to general wear and tear. Each plug pin should be regularly checked along with checks for a bad connection, bad contact, or other damage. The electrical outlets in your property should be checked at regular intervals for any signs of damage or discolouration and where necessary new outlets installed, a new plug on the appliance installed when necessary and checks on the appliance cord.

Back to top

Read more articles

- Log in to post comments