Pat testing. What is a portable appliance test? - Electrical Faults Fixed

Table of Contents

1) What is PAT Testing and Why Should You Care?

Ever wondered if that old kettle or toaster in your office kitchen is safe to use? That's where portable appliance testing (PAT) comes in. PAT testing is a safety check for any electrical items you can move around or unplug which includes everything from your mobile phones charger to the vacuum cleaners at work. Think of it as a health check-up for your electrical appliances and gadgets.

Back to top2) Why Do We Need PAT Testing?

We all use electrical equipment every day, often without knowing whether the equipment is electrically safe. Faulty electrical appliances can be dangerous, potentially causing fires or electrical shock. That's why regular testing of portable equipment isn't just a box-ticking exercise, it's one of the most effective ways to keep people safe.

Back to top3) At Work

If you're a business owner, you have a legal responsibility to keep your employees safe. This means complying with safety regulations like the health and safety at work act. Making sure all your portable electrical devices are in good working order is one way of keeping the health and safety executive happy. Whether you're running an office full of IT equipment or managing a construction site with heavy-duty power tools, PAT testing helps protect everyone. Regular checks on equipment can ensure that electrical faults from developing, giving rise to danger and creating inconvenience with the electrical system.

Back to top4) At Home

While PAT testing isn't a strict legal requirement for homeowners, it's still a smart idea. Think about all the electrical items you use daily:

- Your kitchen appliances like the kettle and tumble dryer.

- Extension leads snaking behind the TV

- Mobile phone chargers that might be getting a bit worn

- Portable devices that the whole family uses

Ensuring that your home electrical appliances are checked regularly can help minimise the risk of electrical fires and other common electrical problems from occurring in the home.

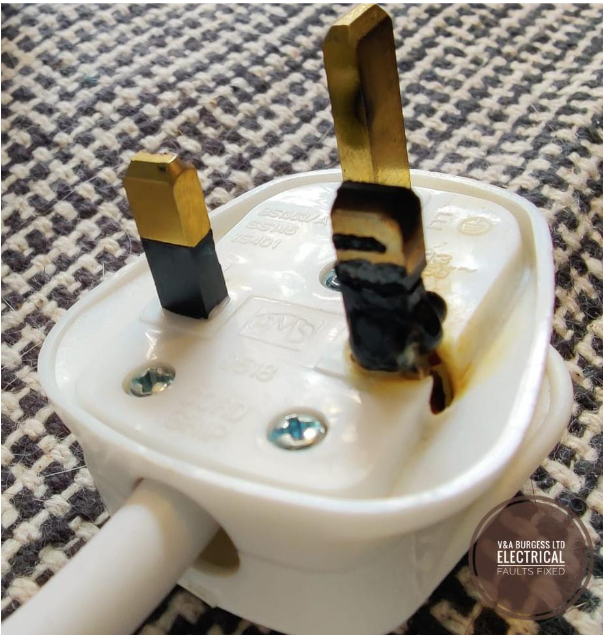

(PHOTO: Damaged Appliance Plug)

Back to top5) What Actually Happens During a PAT Test?

5.1) The Basic Check

First, a competent person (that's someone who knows what they're doing, like a qualified electrician) will do a simple visual inspection. They'll look for obvious problems like:

- Frayed power cords

- Damaged plugs

- Loose wires

- Any exposed metal parts that shouldn't be there

Where items on a visual inspection are found to be obviously damaged, they will likely fail the portable appliances test straight away. A visual examination is the first step in checking that portable items are in a safe condition.

5.2) The Technical Tests

After the visual check, your pat tester will use special equipment to perform several important tests:

- Earth continuity test - Making sure the safety wire (the earth) is properly connected from the appliance case to the earth pin on the plug. The resistance value also needs to be suitably low to ensure that fuses will blow when required.

- Pat insulation test - Checking that the protective covering on wires is doing its job. An insulation test measures the quality of cable insulation within the appliance.

- Checking the lead polarity - Making sure positive and negative connections are the right way round. Reverse polarity can be dangerous.

6) How Often Should PAT Testing Happen?

The frequency of testing depends on how risky your environment is and what type of equipment you're using. Here's a simple guide:

6.1) High-Risk Situations

If you're working in high-risk environments like:

- A construction site

- Industrial kitchens

- Places with lots of heavy machinery

Your portable electrical equipment might need testing every 3 months.

6.2) Lower-Risk Places

In a low-risk environment like a normal office, testing might only be needed once a year. This includes:

- Office equipment like computers and printers

- Kitchen appliances like microwaves

- Extension leads and power cords

For further information on the frequency of PAT testing items used on various sites and premises, consult the government website for the most up to date information.

Back to top7) Common Problems Found During Testing

Many issues found during a formal visual inspection are pretty straightforward:

Worn flexible cable - The appliance cable may have abrasions, obvious signs of wear or cracking to the outer sheath or to both the sheath and inner cable insulation.

Damaged plugs - A damaged plug top on an appliance can be fairly common in high traffic areas as the risk of mechanical damage can increase. The type of electrical equipment can also affect the wear on plug tops and leads with power tools in a working environment often having the most wear of any appliance.

Loose connections to the wall socket - Where the appliance connects to the plug socket on the wall, if the plug feels loose in the socket there could be connections problems, excessive heat generated and risk of melted plug sockets. Whilst this can be a plug socket issue, if the appliance plug feels loose in different plug sockets, it is likely to be the plug top of the appliance that is at fault.

Cracked casings - A cracked case on any electrical appliance is likely to be potentially dangerous. It does not take much further damage to expose live wires and connections when an appliance case is already damaged.

Back to top8) Not all defects are visible

Sometimes, electrical safety defects aren't visible to the naked eye. This is where proper testing of electrical equipment becomes crucial. A full pat test can find:

- Problems with internal wiring

- Poor earth connection

- Failed insulation resistance tests

- Issues that could cause electrical shock

Where defects are found with equipment under the testing process, it’s important to follow the advice of your Pat testing specialist and have repairs carried out promptly to minimise the risk of electric shock, fire or damage to the appliances or electrical system wiring.

Back to top9) If you are a business owner

- Know your legal obligations

- Get a competent person to do your testing

- Keep good records of test results

- Make sure staff know how to spot obvious problems

Keep up to date with the current legislation for electrical safety in your business. There is information on the HSE website that will help you to achieve compliance.

Back to top10) If You're at Home

- Do regular user checks of your appliances

- Look out for warning signs like hot plugs or burning smells

- Consider getting important items tested, especially older electrical equipment

- Don't take risks with damaged power cords

11) Conclusion

Portable appliance testing might seem like just another requirement, but it's really about keeping people safe. Whether you're protecting your family at home or meeting your legal responsibility at work, regular PAT testing is one of the best ways to prevent electrical accidents.

Remember: When it comes to electrical safety, it's better to be safe than sorry. If you're ever unsure about an electrical item, get it checked by a professional. After all, that quick test could prevent a serious accident!

Back to top

Read more articles

- Log in to post comments