Table of Contents

- Why is copper used for electrical wiring?

- The Superior Conductivity of Copper

- What about high voltage lines?

- Durability and Reliability in Electrical Applications

- Flexibility and Workability

- Safety and Standards in the Electrical Industry

- Economic and Environmental Considerations

- Historical and Modern Uses of Copper Wiring

- Conclusion

1) Why is copper used for electrical wiring?

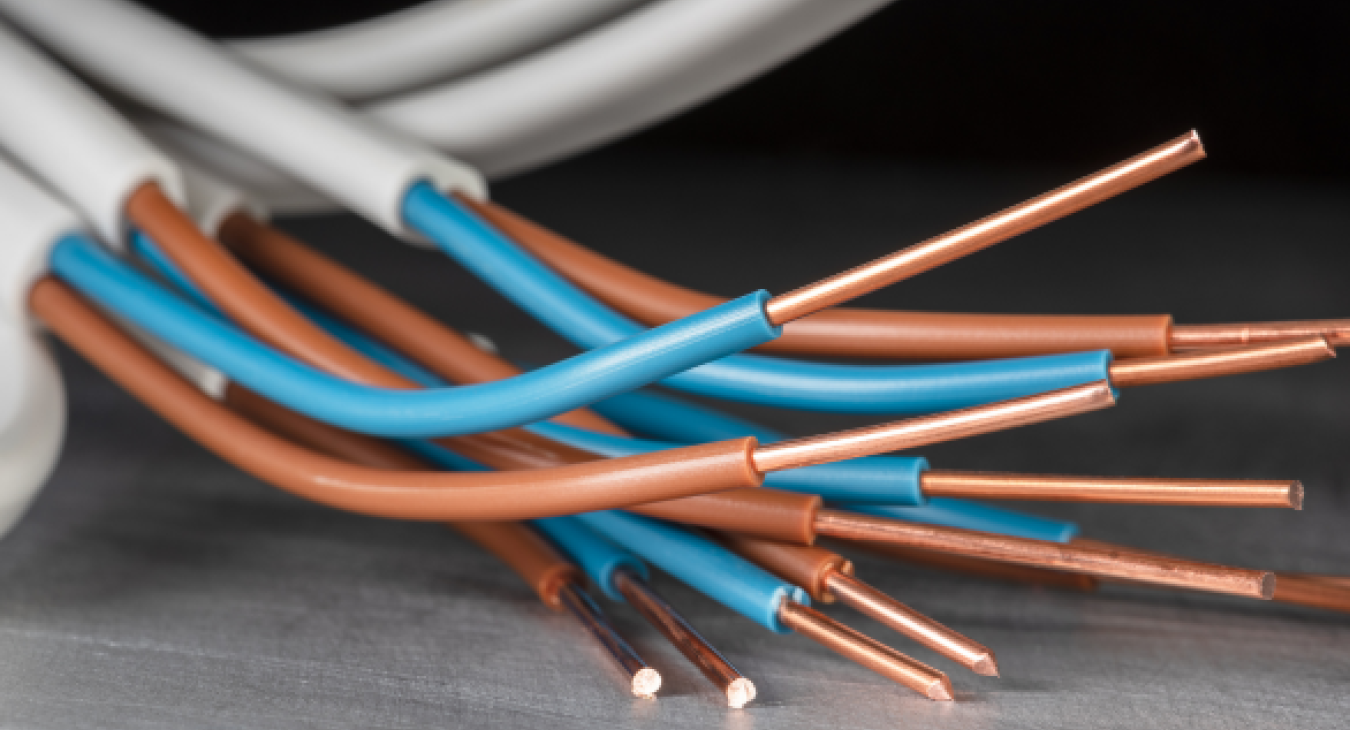

Copper wiring has long been used as the primary metal in electrical systems worldwide. As an experienced electrician and electrical teacher, I know why copper remains the best material for electrical cables, from residential homes to industrial applications. We will look at the many reasons why copper is the preferred choice for electrical wiring.

Back to top2) The Superior Conductivity of Copper

Copper is one of the most highly conductive metals, second only to silver, which is far more expensive and less practical for most applications. Copper's high electrical conductivity makes it an excellent conductor of electricity, enabling efficient transmission of electric current with minimal resistance and voltage drop.

Copper's high conductivity capabilities are due to its atomic structure, which allows free electrons to move easily through the metal. This low resistance is why copper is the preferred choice for electrical wires, particularly in situations where efficiency and reliability are paramount, such as in power cables and high-strength electrical components.

Back to top3) What about high voltage lines?

Where transmission of electricity is needed over long distances, aluminum cores wrapped in steel strands are preferred due to the lower cost and strength. Aluminum is only around 61% as conductive as copper but it is much lighter and when combined with steel reinforcement, it is a viable and sensible solution to power transmission over distance.

Back to top4) Durability and Reliability in Electrical Applications

In my years of working with various types of wiring, I've consistently found copper to be the most durable and reliable material. Copper's high corrosion resistance means it can withstand harsh environmental conditions, making it ideal for both indoor and outdoor electrical applications.

Whether in the damp environment of a kitchen or the exposed setting of outdoor power lines, copper wiring maintains its integrity over a long period, reducing the risk of failure and the potential for residential house fires. Copper wiring systems if looked after can give service for several decades.

The durability of copper is further enhanced by its high tensile strength and thermal resistance. Copper can endure high temperatures without degrading, making it a safe and reliable choice for electrical connectors and other components that may be exposed to heat. This thermal resistance is useful for preventing electrical fires, particularly in high-stress situations where other conductive materials, like aluminum wiring, might fail.

Back to top5) Flexibility and Workability

Copper is not only a highly conductive metal but also a ductile metal, meaning it can be easily bent and shaped without breaking. This flexibility is invaluable in the electrical industry, where wires often need to be threaded through tight spaces, into tight terminals or around obstacles in construction tools and commercial buildings. Unlike aluminum wire, which is more brittle and prone to breaking, copper can be manipulated into thin wires without losing its structural integrity or conductivity.

This workability extends to the manufacturing of electrical wires, where copper's ductility allows for the production of various types of copper wire, each suited to different applications.

Aluminum wiring was used in the United Kingdom for a short period of time in the 1970s during the copper shortages.

Unfortunately, aluminum is a rather fragile metal when compressed into screw terminals as would be found in fuse boxes, consumer units, plug sockets and switches. As a result, I commonly find that homes with aluminum wiring end up with burnt out circuit breakers and melted connections.

Aluminum simply crushes when tightened up and as a result, connections can still be loose which can lead to overheating and fires.

Back to top6) Safety and Standards in the Electrical Industry

Safety is a paramount concern in the electrical industry, and copper wiring plays a central role in meeting the strict safety standards set by regulatory bodies, particularly in the United States. Copper's combination of high electrical conductivity, thermal resistance, and high melting point ensures that it remains safe under various operating conditions. This is especially important in critical applications such as electrical wiring for kitchen appliances, where the risk of electrical fires must be minimized.

Copper's high strength and resistance to corrosion make it a popular choice for electrical conductors in both residential and commercial applications. Its reliability ensures that electrical systems remain safe and functional over time, reducing the likelihood of failures that could lead to dangerous situations.

Back to top7) Economic and Environmental Considerations

While copper may be more expensive than some alternatives, such as aluminum wiring, its long-term benefits far outweigh the initial costs. Copper’s durability and low maintenance requirements make it a cost-effective choice for electrical cables in the long run. The high corrosion resistance and reliability of copper wiring mean that it rarely needs to be replaced, further enhancing its economic value.

Additionally, copper today is a highly sustainable material, as it can be recycled without losing its properties. This recyclability contributes to a circular economy, where copper conductors can be reused in various applications, reducing the need for new raw materials, and minimizing environmental impact. The fact that copper is a common material in the electrical industry, yet maintains such a high level of performance, is a testament to its enduring value as the gold standard for electrical wiring.

Back to top8) Historical and Modern Uses of Copper Wiring

The use of copper wiring dates back to the invention of the telegraph and the telephone, where its excellent conductivity made it the best conductor of electricity for early communication systems. Over time, copper's role has expanded to include a wide range of applications in modern electrical systems, from small amounts used in electronic devices to large-scale power cables that supply energy to entire cities.

Today, copper wiring is still considered the best choice for a variety of applications, from domestic wiring in residential houses to industrial applications requiring high-strength, heat-resistant cables. The widespread use of copper in electrical lines and power generation systems underscores its status as the material of choice for professionals in the electrical industry.

Back to top9) Conclusion

Copper wiring remains the preferred choice for electrical cables due to its superior conductivity, durability, flexibility, and safety. As a reddish metal with a high melting point, copper is not only the best metal for conducting electricity but also the best option for ensuring the long-term reliability and safety of electrical systems. Whether in high-voltage power lines or the wiring of kitchen appliances, copper's role as the primary electrical conductor is unrivalled, making it the gold standard in the electrical industry.

Read more articles

- Log in to post comments