Can We Use Tape To Connect Electrical Wires Together? - Electrical Faults Fixed

Electrical wires carry the electrical current around our home to the plug sockets, light switches, junction boxes and other electrical accessories. These cables are safely protected by a PVC outer jacket or ‘sheath’ that prevents access to dangerous live wires. This layer of insulation also offers some abrasion resistance.

The integrity of the covering on these bare copper wires is vital to ensure that no-one receives electric shocks but is it safe to repair them by TAPING WIRES TOGETHER or is that dangerous?

There are many poor and proper methods to repair electrical cables in the home which we will cover in this article that include:

- Duct Tape

- Wire nut connection

- Junction boxes

- Lever connections

- Crimping

- Soldering

- Heat Shrink

- Twisting together

- Choc blocks

1) Duct tape

I hope this is an obvious no but we will venture here anyway. Taping wires together using duct tape is ridiculous and should not be used as a method of electrical connections. This is likely to breach the wiring regulations or wiring code wherever you are and is not a long-term solution or even a safe temporary solution.

Pros: None really

Cons: Lots of problems and electrical danger

Back to top2) Wire nut connections

These are a plastic cap connection that contains a metal inside. The idea being that the wires are either inserted and twisted together or inserted and squeezed together. Regardless of the suitability of each type of connection method, wire nuts are likely to also require enclosing in some form of enclosure so single cable covering insulation is not visible or likely to suffer mechanical damage.

These connections should ideally be accessible for maintenance in the future.

Pros: Relatively inexpensive and quick to use

Cons: May require maintenance, may not make great connections if used incorrectly

Back to top3) Junction boxes

Junction boxes are a great way to join cables safely. There are two kinds and many types. The two different kinds are:

Maintenance Free and Non-Maintenance Free.

A maintenance free junction has been designed by the manufacturer to be installed and forgotten essentially. This type of junction, if installed according to the manufacturer’s instructions, should not require any maintenance once installed.

A non-maintenance free junction box is something that will need to remain accessible for maintenance throughout its life. This type of junction box will possibly have screw type terminations that may require tightening throughout the lifespan of the junction.

Pros: Specially designed for joining cables, inexpensive

Cons: Access needed for maintenance, bulky in some cases

Back to top4) Lever connections

Lever connections are a little more pricey than other forms of joining cables but are engineered fantastically. These connectors are available for almost every kind of cable you would want to join and have a corresponding enclosure to ensure that cabling is safe.

One of the major manufacturers of lever connectors is WAGO. WAGO manufacturer a connector for almost every situation and their engineering and build is fantastic.

For connections to be safe, they must be installed in the correct junction box as wiring regulations in most countries will not be happy with single cable insulation hanging around and will want connections enclosed.

Pros: Quick easy installation, many are maintenance free

Cons: Expensive compared to other methods

Back to top5) Crimping

Connecting wires together by crimps is a fairly good method in most cases. Crimping is a method that involves crushing an insulated or non-insulated connector onto wiring. There is usually a correct tool for each type of crimp and its important that the right tool is used otherwise the connections will not hold.

A relatively inexpensive form of connecting wires, but will either need an enclosure or junction box to contain any single insulated wiring normally.

Pros: Can form a reliable connection, inexpensive crimps parts

Cons: Tool could be expensive, easy to get wrong

Back to top6) Soldering

Soldering cables is the process of using molten metal to form a reliable connection between two wires. The idea being that the connection is permanent once done and creates a solid conductive metal bridge between the two parts.

A soldering iron is used to melt the solder onto the wires leaving a permanent connection behind. Should be maintenance free.

Pros: Can create reliable and maintenance free connections

Cons: Tricky in confined spaces, need a soldering iron

Back to top7) Heat Shrink

This is usually a process carried out after repairing the damaged wire. Heat shrink tubing is a material that shrinks when heat is applied to it. This should be carried out after crimping or soldering to provide a ‘jacket’ for the joined wires.

Heat shrink does not necessarily provide the same level of protection as the manufacturers original cable sheath would but is better than taping in most cases. Tape can come off over time and leave connections on display once again.

Back to top8) Twisting Together

Twisting wires together without another form of connection is not great. This wiring method will make the metal wire brittle in most cases of solid copper wires. In the case of stranded wire twisting together cables can make a mess that may need re-terminating.

If twisting cables together, another method should also be employed such as choc blocks or soldering.

Back to top9) Choc Blocks

Choc blocks are a metal connection encased in PVC or plastic. These are a screw tighten terminal where cables are inserted together and a screwdriver is used to tighten the connections. These types of connection should also be used in conjunction with a junction box to ensure that there is no single cable insulation on show.

They are widely available and relatively cheap so they are still quite popular. The connections are not a maintenance free type connection and will need to be left accessible for future maintenance or replacement.

Pros: Cheap, relatively quick to use

Cons: Can take up a lot of space, need access for maintenance

Back to top10) Can wires be taped together behind electrical sockets?

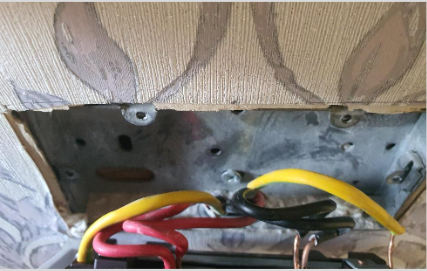

Where electrical outlets have electrical wiring that has been shortened over the years, it may be necessary to extend the cables behind when replacing a plug socket.

The best way is to find a new socket that fits the old wiring without having to lengthen or shorten any cabling but this is not always possible. TAPING WIRES TOGETHER without some other form of connection mentioned above is potentially dangerous and can lead to loose connections and burnt plug sockets.

Extending wires behind a single plug socket is likely to lead to problems due to the lack of space in the back box or receptacle outlets or back boxes for single sockets.

It may be necessary to convert a single plug sockets to double sockets where extra space is required behind for extending wires. There is also the option of a box extension or a surface mount box to create more room.

A qualified electrician should be consulted where electrical work involving extending wires needs to be extended as power lines can cause electrical hazards if tampered with or unsafe work is carried out.

Electrical safety is paramount whenever working on electrical plugs or other electrical devices and without the correct knowledge, tools and testing equipment, there is no guarantee of safety.

Back to top11) Can an extension cord be repaired with tape?

Where wire insulation on power cords have become damaged on pop-up sockets, a power strip or extension leads it is often a safer solution to replace the whole item or at least the entire cord if possible. Small appliances have their own plug and electrical cord and if these become damaged then the cord should ideally be replaced from plug top to appliance in its entirety.

Repairing electrical cords with tape is never a good idea due to their exposed nature. Appliance cords and extension lead cables are more at risk of damage than wall socket cables or other wiring buried in the walls.

As a result, any damage that has occurred in the first place is likely to reoccur without considering the cause of the damage and prevention.

If the damage to the extension cord is due to overload then check that the lead is not faulty or you are not overloading the lead.

Back to top12) What about very low voltage cables > 12 volts?

Whilst the risk of electrical shock is very low indeed in 12-volt home wiring systems, there are still better ways of joining electrical cables than a roll of electrical tape. In order to create long-lasting connections, one of the methods above is better used.

Back to top13) Summary

Where electrical equipment has exposed wires that require repair, TAPING WIRES TOGETHER is not recommended. Electric shock may occur if bare wire is allowed to show through and without a full and more permanent solution using some of the methods above, there are also likely to be electrical fire hazards and issues with short circuits present with taped up wiring.

Remember that electrical appliances and in particular high-powered appliances such as a washing machine or other electrical equipment with a heating element are likely to place great demands of plug tops and the flexible electrical cord.

Where there are large demands of electrical cabling, any repairs should be carried out properly so as not to leave potential hazards.

The only time it is acceptable and common practice to tape wires together is when securing cables out of the way whilst carrying out works, identity marking to cables, temporary protection from finishing plaster and such similar situations.

Back to top

Read more articles

- Log in to post comments